Hello, and welcome to Cloud Riders Store, where I design, manufacture and sell accessories for Storz & Bickel Vaporisers (source manufacture). At the moment I’m working on few projects, the Mighty Grinder is the main one. It’s a Grinder that fits on the Mighty & Crafty vaporiser, using a similar filling aid device so you can grind right into it and savour every trichome. Also I’m in the middle of moving from Melbourne to the Netherlands and I’m almost finished designing and testing a Charging Stand for the Mighty.

I tested positive for Covid on Saturday, so I wasn’t able to work to full capacity this week, especially with the Mighty sitting in the pit stop, as my lungs were given the Black and Orange flag the first few days.

Nevertheless, I have exciting news regarding Production: An important figure in the plastic industry has reached out to me and offered to quote the grinder, and I’m not talking about someone in sales, I’m talking about a Chairman of a major international plastic company.

I share my post to few Facebook groups and Mark Harwood the chairman of Barkley Plastics commented on my last post saying that “This product should be moulded and not 3d printed” and offered to quote the product.

At first I didn’t know who I was talking to as I was as sick as a dog. I continued answering other’s comments about moulds, cost and other things and not answering his offer as I didn’t want to say something wrong. I was so sick I wasn’t thinking straight. I just needed time and luckily he was patient.

The day after testing positive was the worst day for me. I couldn’t eat or drink, no vape and no sleep, it was an awful 24 hours. The race was good though, but that was it.

Monday when I was coming back to life, I started communicating and shared the CAD files with Mark on Tuesday. Now I’m waiting to hear back. I’m very, very excited and hopeful.

I’m sure that Barkley plastic is not after what’s in my bank account now, and a successful man like Mark will not bother with my product unless he sees a real potential in it.

Barkley Plastics, is a major name in the plastic industry and trusted by companies like BMW, McLaren, Jaguar, and Nissan, The list is long…

For the grinder to be made in the UK by such a reputable name will be a major leap forward. This will be a real high quality product.

Now to bring the product closer to market and achieve maximum customer experience enhancement, I had to use my “yet to be” assets to create a second product that will benefit my “yet to be” customers.

The product is a package of five Filling Aides, in five different colours, so you can tell what strain is in which Filling Aide. At the moment I’m thinking transparent, white, red, green and orange. Maybe we will release pink and blue on Valentine’s day.

The five Filling Aid package should retail around the $30 USD (price is not final yet) but in order to achieve this I had to consider a different material. I have been advised by industry experts to use food grade PC instead of Peek. So based on their advice I’ve decided to make the plastic parts out of PC, which will allow us to release the Filling Aids in different colours, so you can use a Different colour for each strain.

When starting an Indiegogo campaign, you have to choose the product’s stage.

As I want to choose prototype, I have to provide the video and the pictures mentioned above. While recording the video, the 3d printed plastic teeth didn’t fully function, not the way they should anyway.

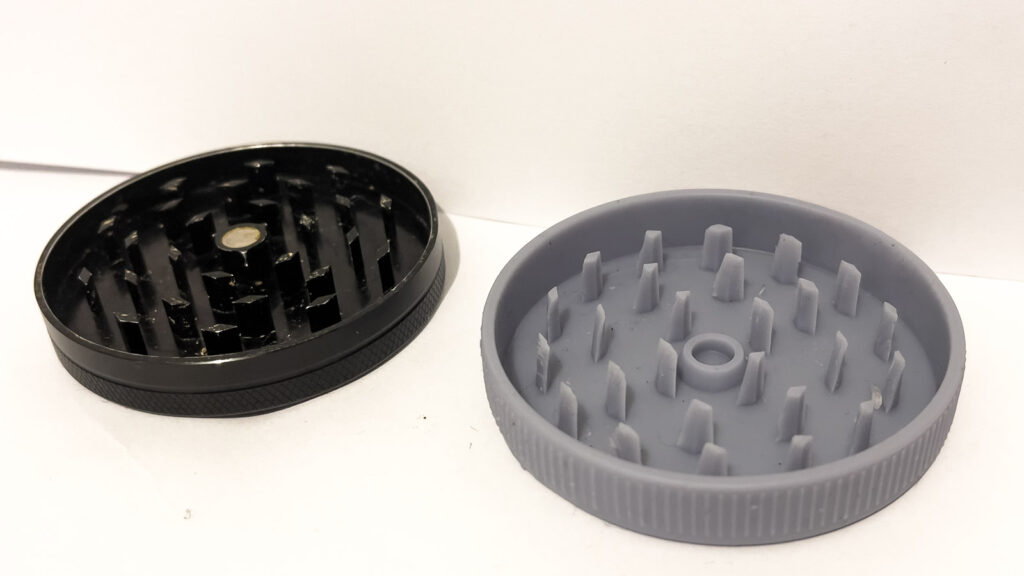

As you can see in the picture my 3d printed teeth are not complete and not strong enough, (not as strong as normal plastic), so the video didn’t pass my quality control.

For me to be able to record a video I will need functioning teeth, so for that I’ve ordered the Aluminium parts to be printed using Selective Laser Melting (SLM) from Craftcloud3d. I have to say though that things don’t sound promising as they came back to me with a few serious problems.

If we manage to solve them, then the parts are supposed to arrive next week and I will be able to record a video with a fully functioning grinder. Otherwise, I have to find someone else to print or CNC the aluminium parts so I can record the video to use for marketing and start the Indiegogo Campaign, Link to the pre campaign if you didn’t sign up.

Thanks for reading 😊 🙏 and catch you next week ☮️