Hello, and welcome to Cloud Riders Store, where I design, manufacture and sell accessories for Storz & Bickel Vaporisers (source manufacture). At the moment I’m working on few projects, the Mighty Grinder is the main one. It’s a Grinder that fits on the Mighty & Crafty vaporiser, using a similar filling aid device so you can grind right into it and savour every trichome. Also I’m in the middle of moving from Melbourne to the Netherlands and I’m almost finished designing and testing a Charging Stand for the Mighty.

It has been a busy week, I’ve fired one of my potential suppliers, the one that was making the sample, and look like I will be partnering with a distributor in Toronto, and I’m in negotiations with another one in NY. Soon we will have a sales team.

And I’ve started my Pre-Campaign on Indiegogo.com, click here if you want to Sign Up

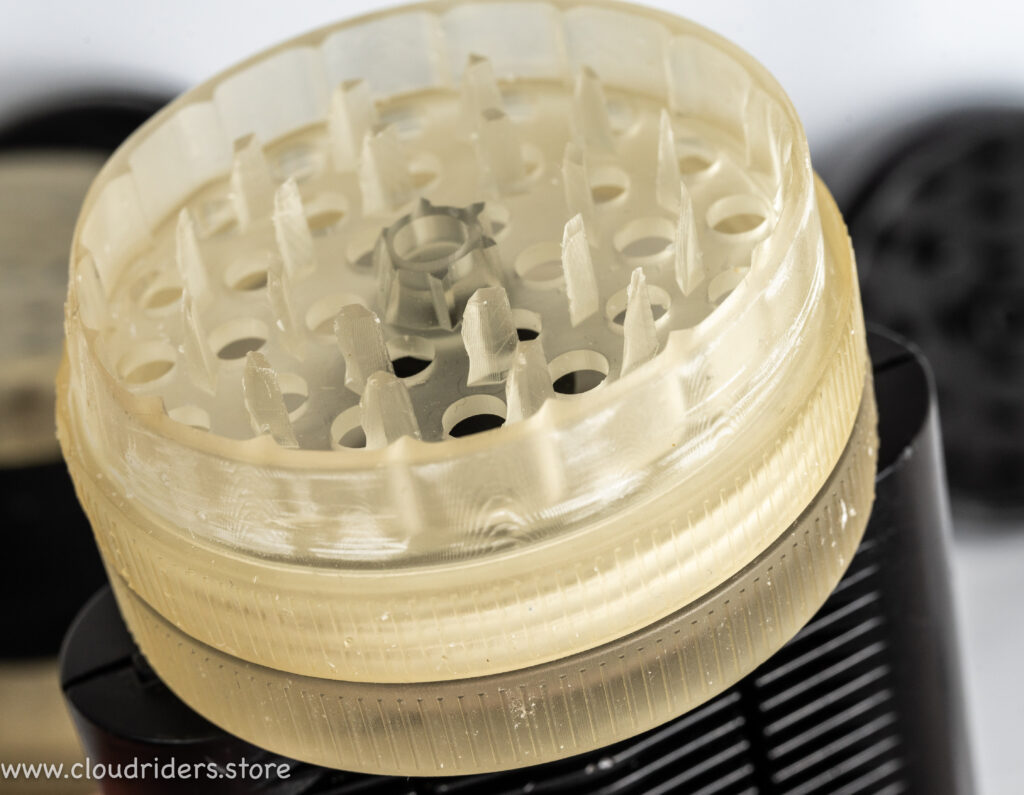

But as I promised last week, these are the shots of the printed prototypes.

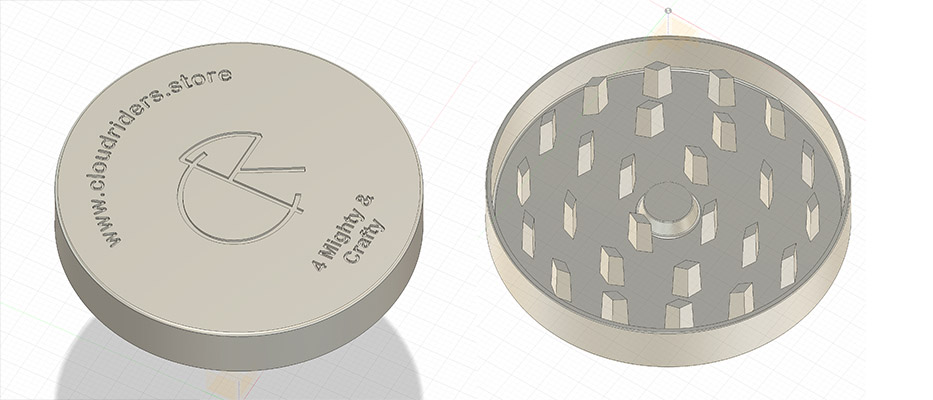

So the grinder itself, is a simple grinder, I didn’t reinvent the wheel, I just canceled the forth layer, honestly I don’t understand why would you separate your herbs from their Trichomes, it’s like keeping your favourite chocolate until the end. I say let us eat the best chocolate now.

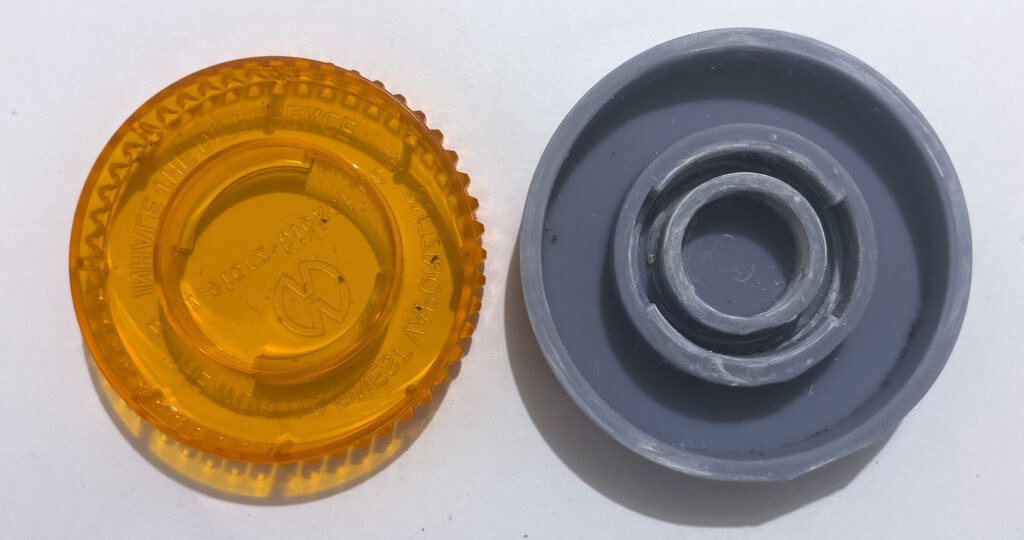

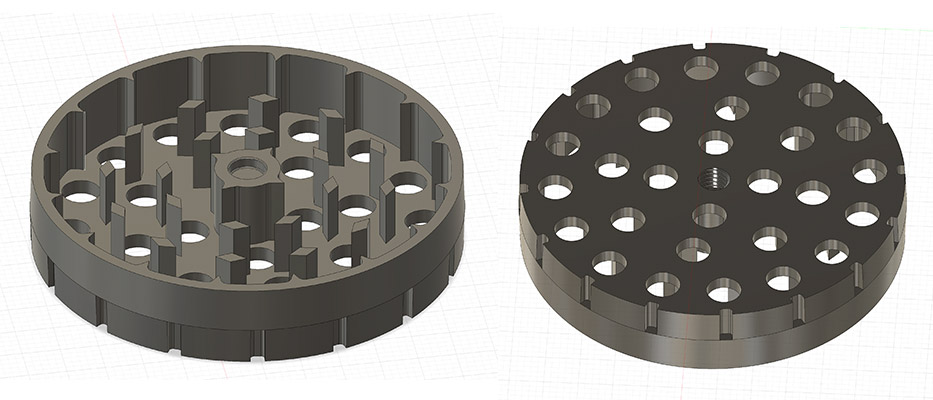

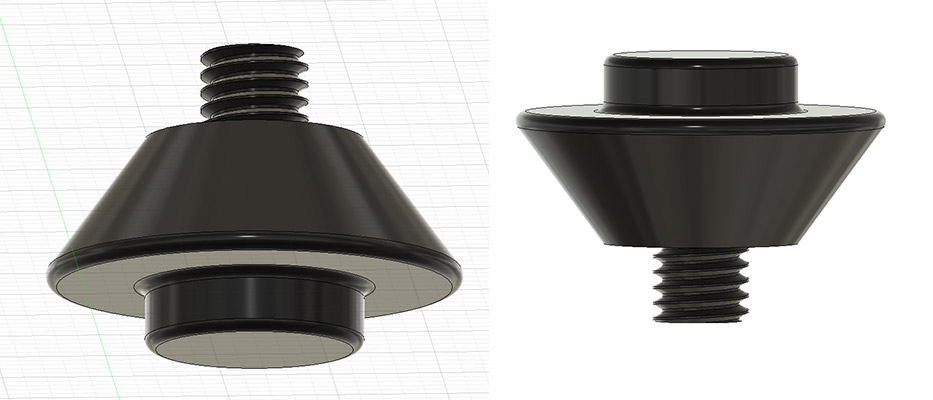

As you can see, Just a simple Grinding plate, obviously this is a 3d printed prototype, the grinder will be made out of Aluminium. 6061 T6 and it will be sand blasted and anodized.

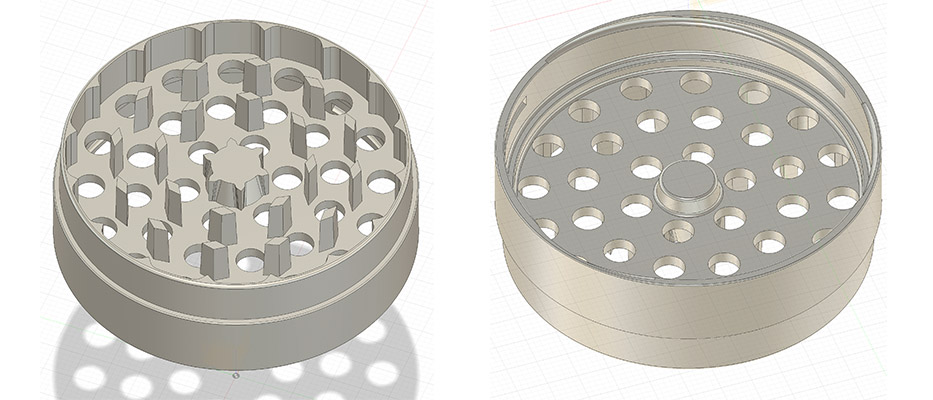

And here are all the grinder parts. Missing the magnets.

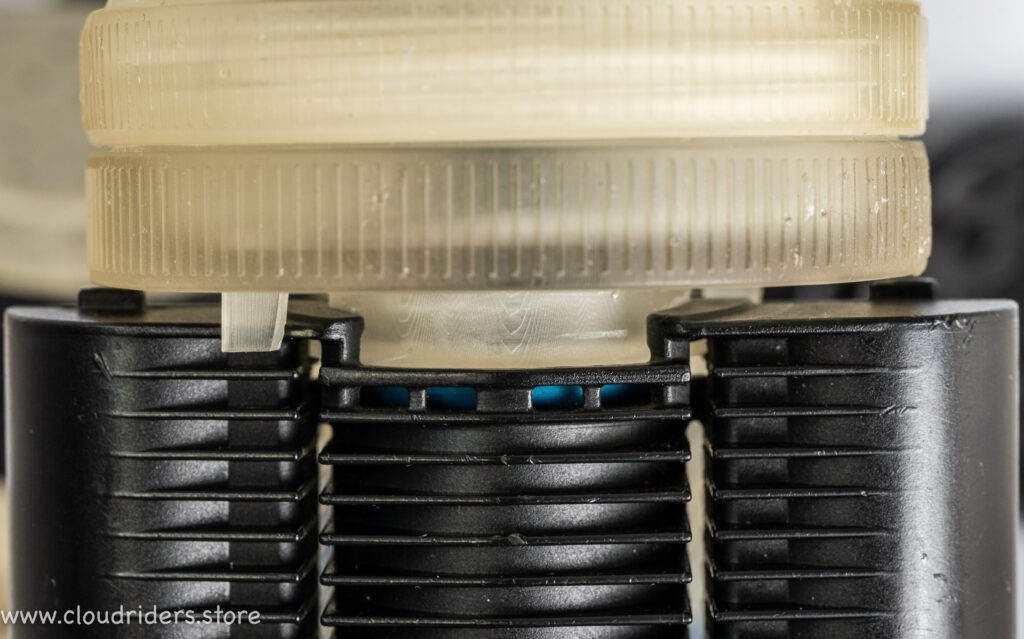

Now Obviously this isn’t the ideal way to grind, But this is the grinder on the top of the filling aid, and the filling aid is fitted to the mighty.

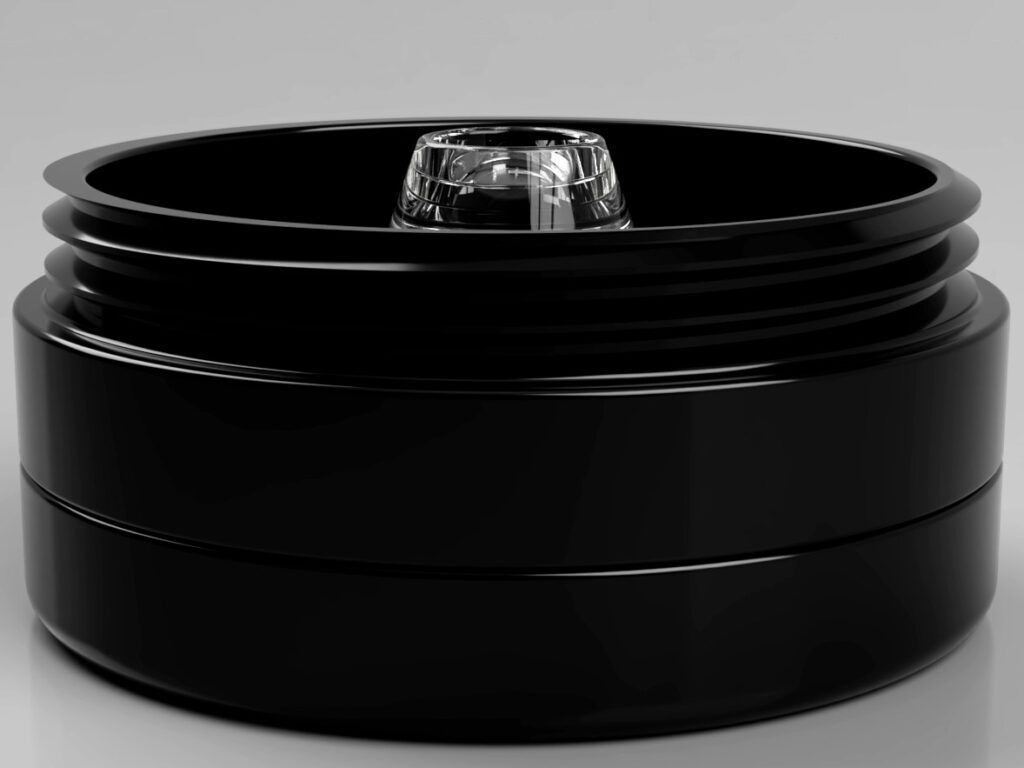

And this is the filling aid without the grinding bit, fitted to the Mighty

As you can see from here, It’s a perfect fit.

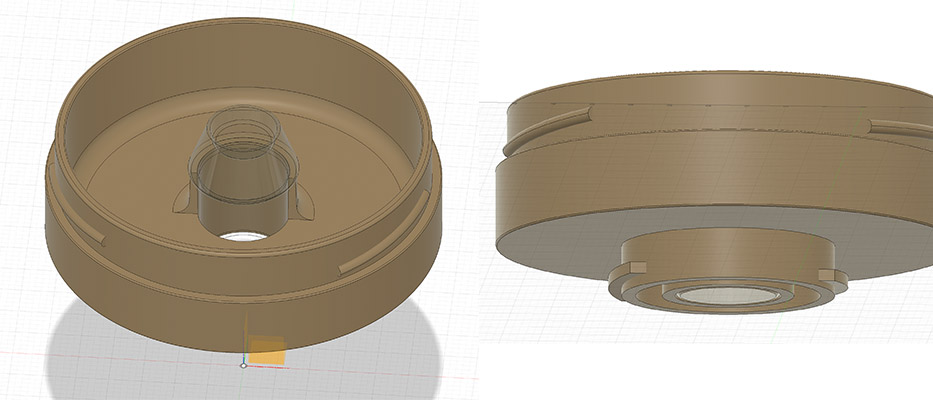

As you can see my filling aid is bigger, allowing you to store more herbs, but also because it’s air-tight, the herbs will stay fresh for much longer.

As you can see, It’s a perfect fit. as if it’s made for the Mighty & Crafty 😉

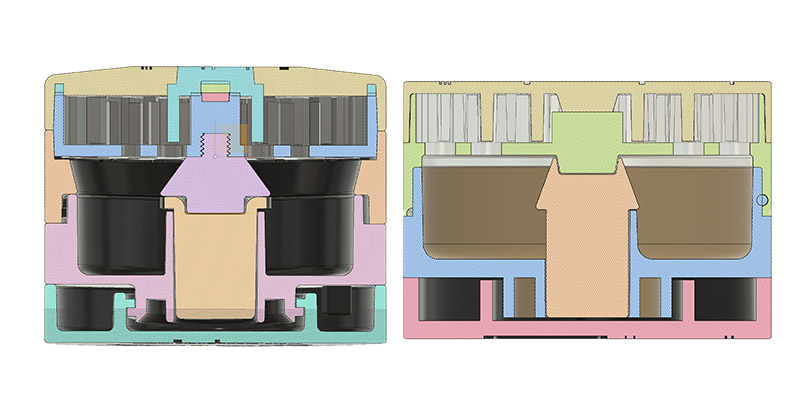

And this is the filling aid with the lid instead of the grinding bit, so as you can see the Grinder is interchangeable with the filling aid so in the picture below you can see the other configurations

In this picture you can see three configurations, starting from the right, that is the grinder without the lid screwed to the filling Aid.

And in the middle we have the grinder with the filling aid, so this is how you will grind if you want to fill the Mighty or the Crafty after.

And then on the left top we have have a Filling Aid and below it, flowers storage.

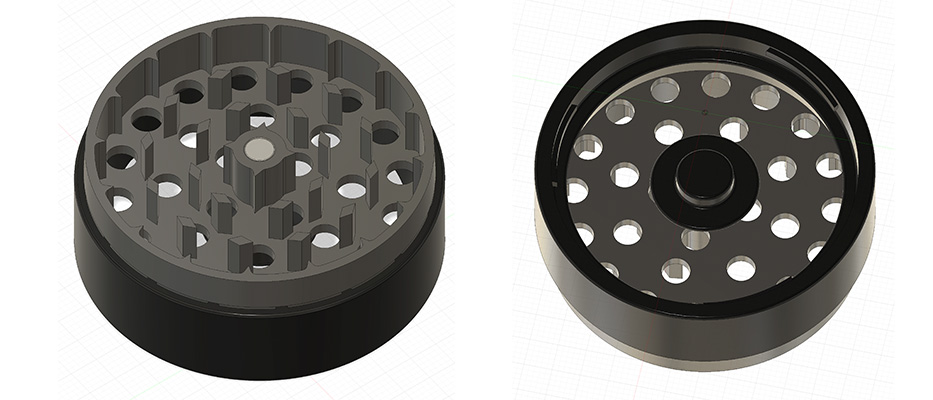

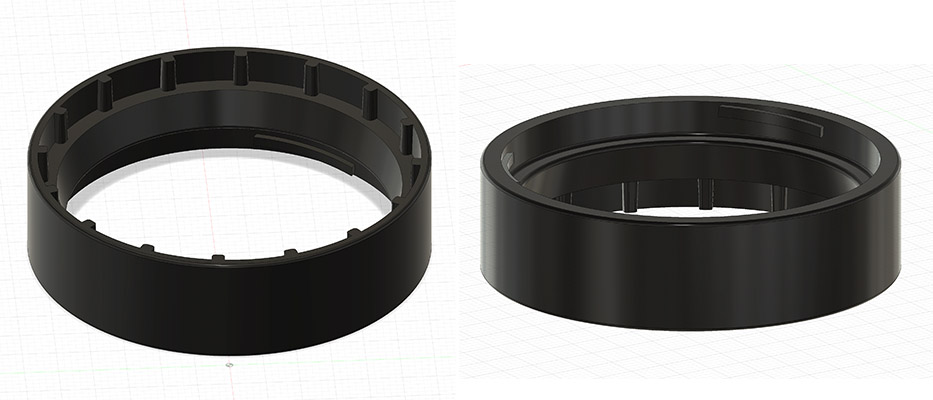

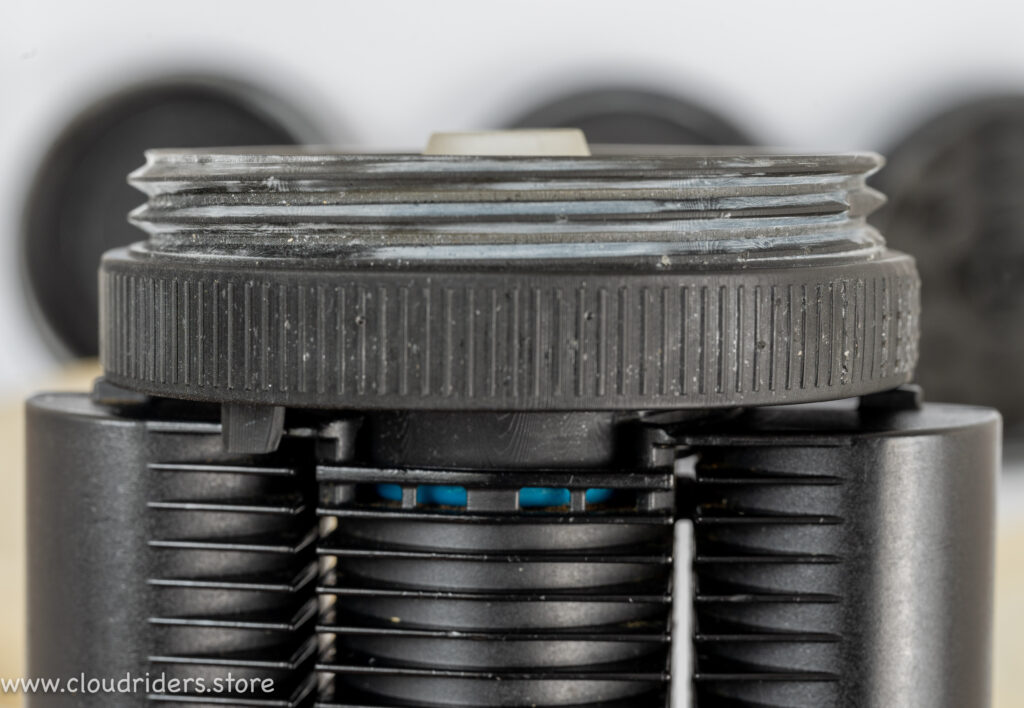

These are the filling Aids without the Lid, you can see the thread, same thread like the grinder, same diameter.

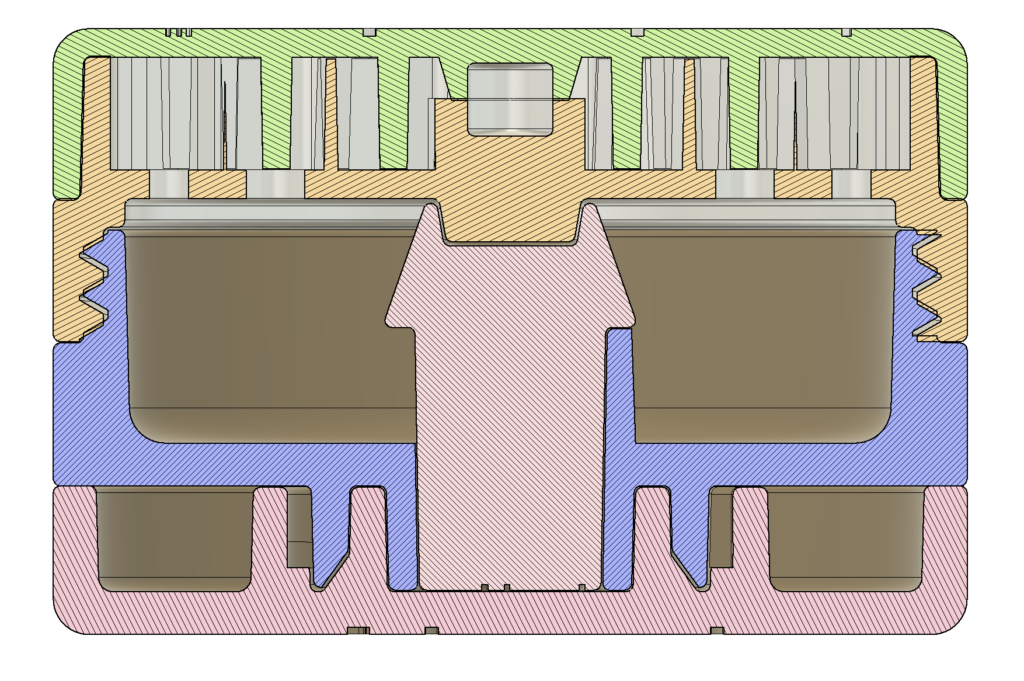

Here You can see how it’s made to fit the Mighty & Crafty and you can see the new upgraded bottom cap, with air-tight design.

So now after looking at all the pictues, I’m thinking Black shouldn’t be the only colour, I’m happy I’ve printed with different colours.

And finally in this picture you can see how I got around getting the plug full of herbs, everytime you fill the stock filling aid.

I have been talking about water proof, and I’ve achieved it, the new design is water proof, and I don’t mean the grinder itself, but I mean the Filling Aid.

This 3d printed Filling Aid is water proof, so if it’s on a table, “At the end of the party and it’s the last herbs left”, and the inevitable beer spill happens, your herbs will stay DRY.

In my head, I can hear the crowds cheering in the background, “Waterproof! WOW, You are a genius” lol.

Now again, not to take it scuba diving.

I have to point here, that my 3D print is nowhere as accurate as industrial printing or moulded plastic, and the material will play a major role also, so; What I’m trying to say is the product will be of better quality.

I added Knurling as you can see in the pictures, so it’s not slippery, especially in the cold.

I have been using the filling aid for few days now, and the only improvement I’m going to make is to the thread, I will make it a bit shorter, will do that over the weekend before printing with ABS like material, this will be my last print.

But on the subject of prototype & final design I think I will keep on adding improvements to it, well until I can’t because it’s in your hand.

Apart from that, we are very close to the release, I think next week I will have a date for the first order.

That’s all for this week, stay safe and peace ☮️