Hello, and welcome to Cloud Riders Store, where I design, manufacture and sell accessories for Storz & Bickel Vaporisers (source manufacture). At the moment I’m working on few projects, the Mighty Grinder is the main one. It’s a Grinder that fits on the Mighty & Crafty vaporiser, using a similar filling aid device so you can grind right into it and savour every trichome. Also I’m in the middle of moving from Melbourne to the Netherlands and I’m almost finished designing and testing a Charging Stand for the Mighty.

You guessed it, I bought a 3d printer, nothing fancy though, just to finally really rapidly prototype, and we’ve been busy, Learning to 3d print and rapidly prototyping, lol.

It’s great, I have printed three filling aids, just to perfect the fit on the mighty, not loose, but not very firm ;), and I believe I’ve nailed it, while I’m writing this post, the Anycubic Photon Mono 4k is printing the last plastic prototype, I hope. 🤞

This is the previous print, you can see clearly, I’ve printed it on the plate because the one before failed, one of the part didn’t stick, but I was printing horizontally, this one I’ve printed vertically as you can see, I have to say the printing quantity is pretty impressive, look at the engraving from this $300 printer comparing to last week prints.

Apart from fiddling around with the printer, I belive I’ve achieved an airtight filling aid, let me show you how.

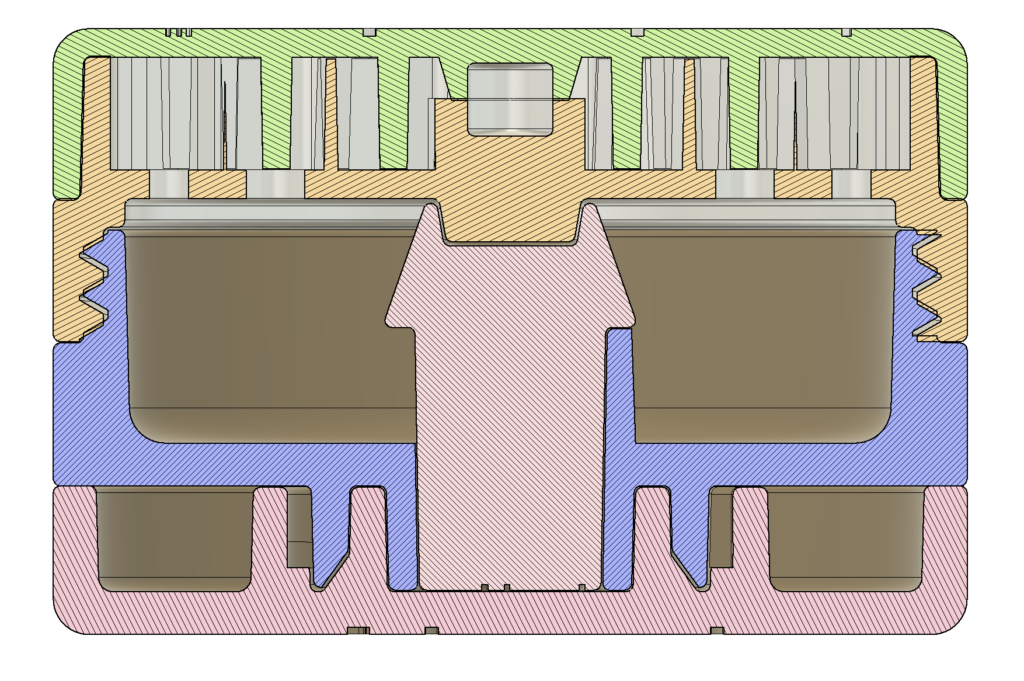

As you can see in the section analysis, I’ve ditched the old locking mechanism I was using, and used normal thread, now to achieve that, I had to extend the diameter farther more to 62mm, nothing major, but the grinder now is chubbier and stocky, a handful. Walls are seriously thick also, nothing under 2mm,

Another major change is the bottom cap of the filling aid, and while the OEM was obviously designed not to be airtight, mine is.

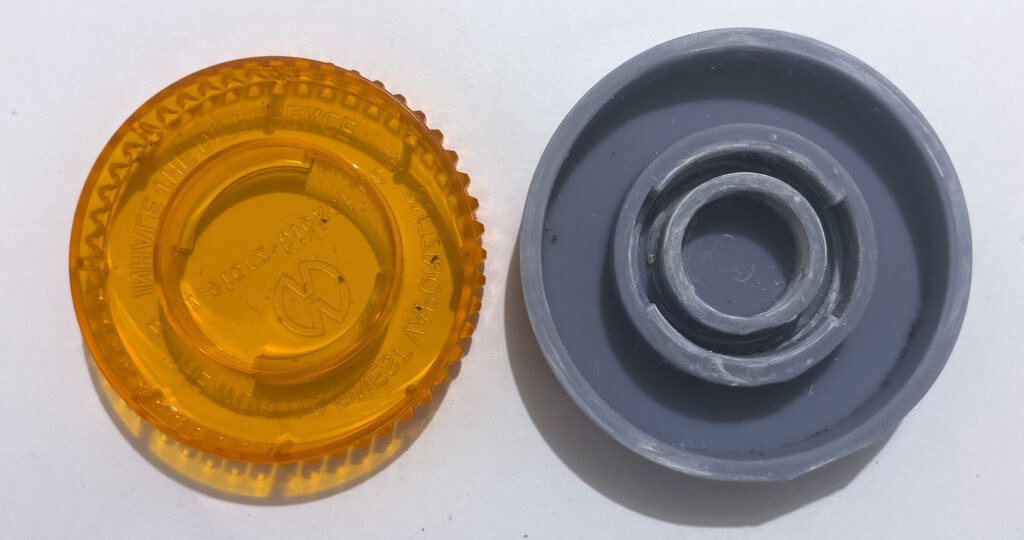

Now, If We take a close look at the original bottom cap from Storz & Bickel, We can see clearly the opening, I’ve never understood it’s purpose, Dazzling.

Mine won’t dazzle the same way, opening and gaps are made for a reason, not for ventilation.

Obviously I’m obsessed with flavours, I keep my coffee beans in the freezer and I grind my Mint, Oregano and Basil just before using them, and whatever grounded, I like to keep in airtight containers.

And for that purpose I added few walls, closed few gaps, made the walls thicker so it doesn’t break after the first impact, and fingers crossed it will pass the water proof test, now I’m not saying; take it swimming, but as good as it could be considering it’s handicap.

Another upgrade happened to the plug, or as I like to call it the asher, Someone once told me Size matters, so I made the walls 8.6mm high, so you can hold them with your fingers even if you were wearing gloves.

And I sealed it from the top, so it’s not part of the container.

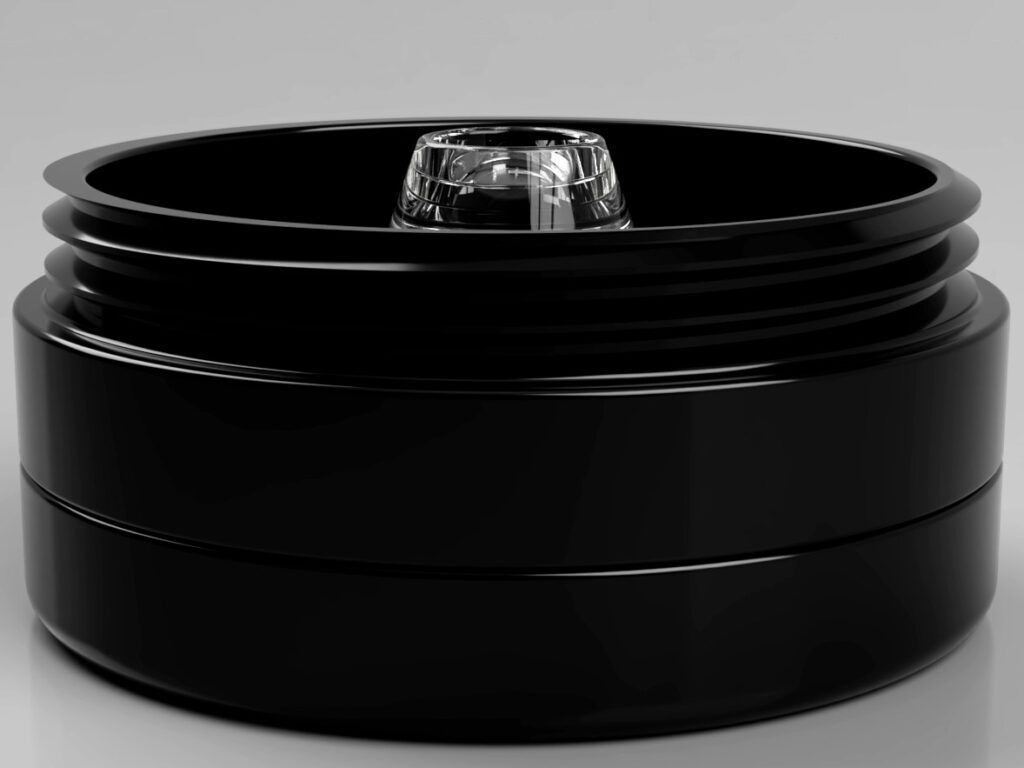

All an all, I think I have an awesome Grinder, the 3D print just came out, it fits perfectly together and on the mighty, so I will be sending the design to get the Aluminium prototype made, it’s late, so I’m not going to take pictures of the 3d print now, as one of the parts is not perfect, and I have to print it again, but I have few renders that I’m going to share with you. and I will have nice pictures of the 3d print next week.

That’s all for this week, stay safe and have a good weekend, ☮️

Very good blog post. I absolutely love this website. Keep writing!